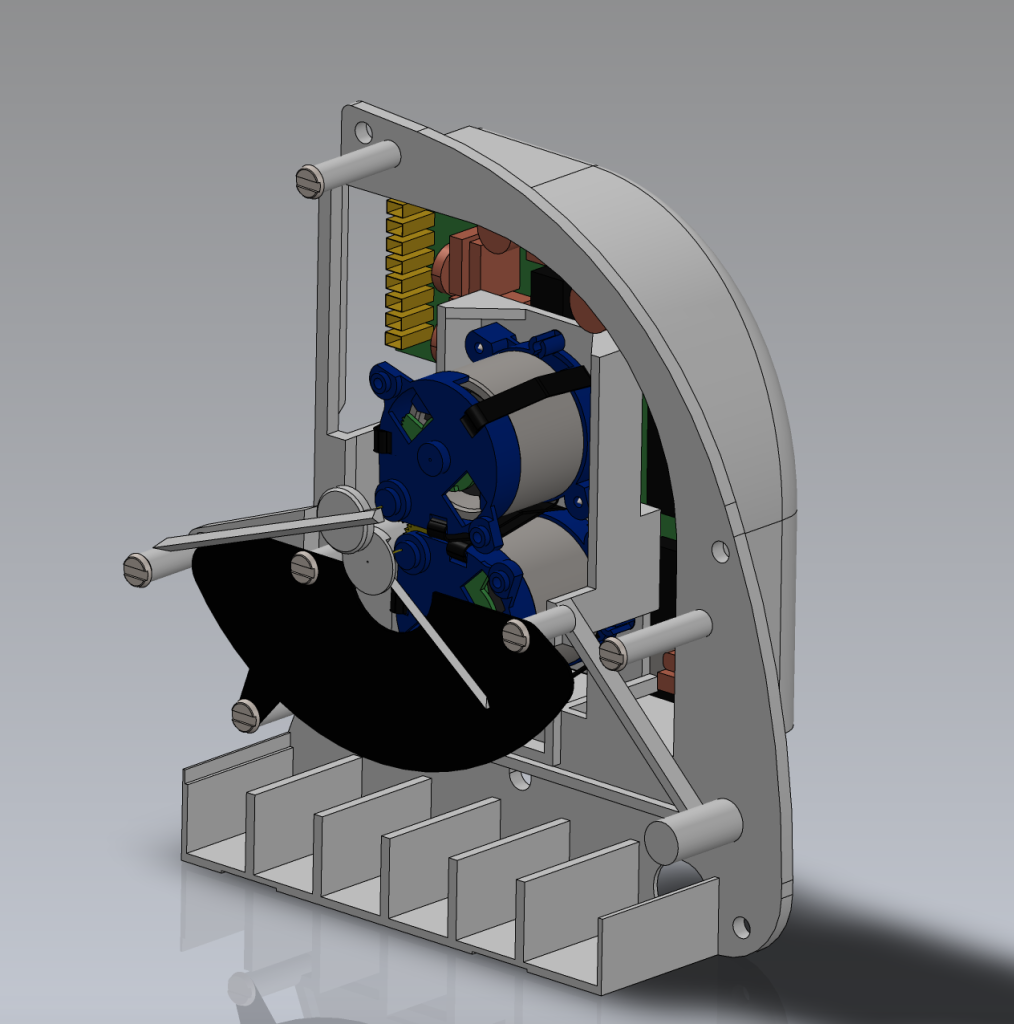

This reverse engineering project was a great introduction to Solidworks and 3D modeling. This was a sophomore assignment and my first attempt at using any kind of a CAD software for something serious, but it came out well. Here you’ll find a gallery and some commentary on the project and how it came together.

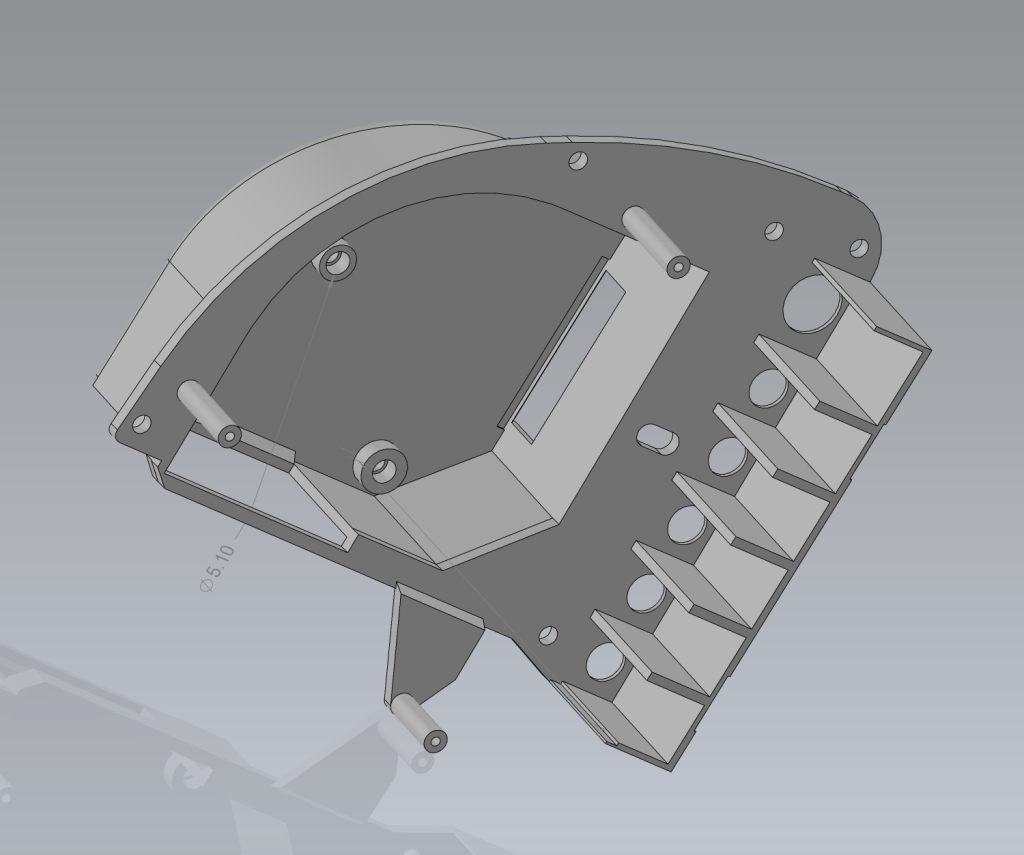

The assignment outline was to find some sort of object that had at least 30 to 50 distinct parts. We then had to find dimensions for each part and model them using Solidworks to create a final assembly of the object.

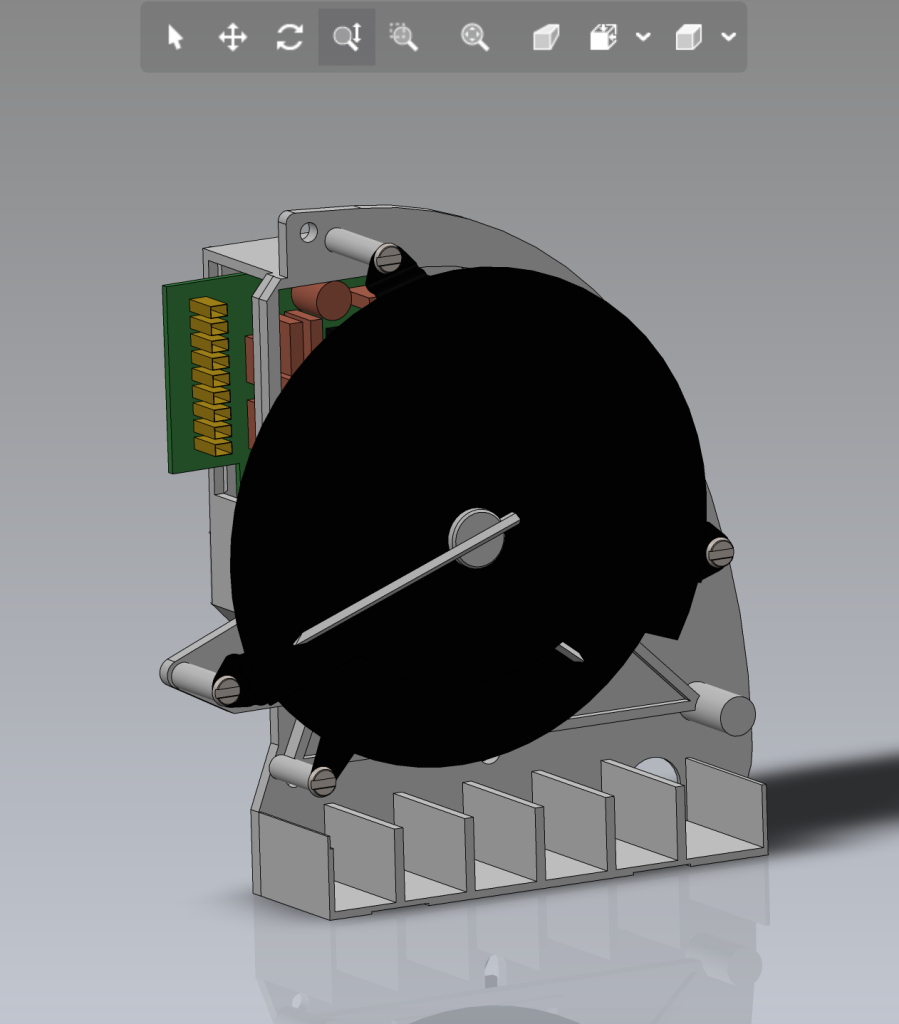

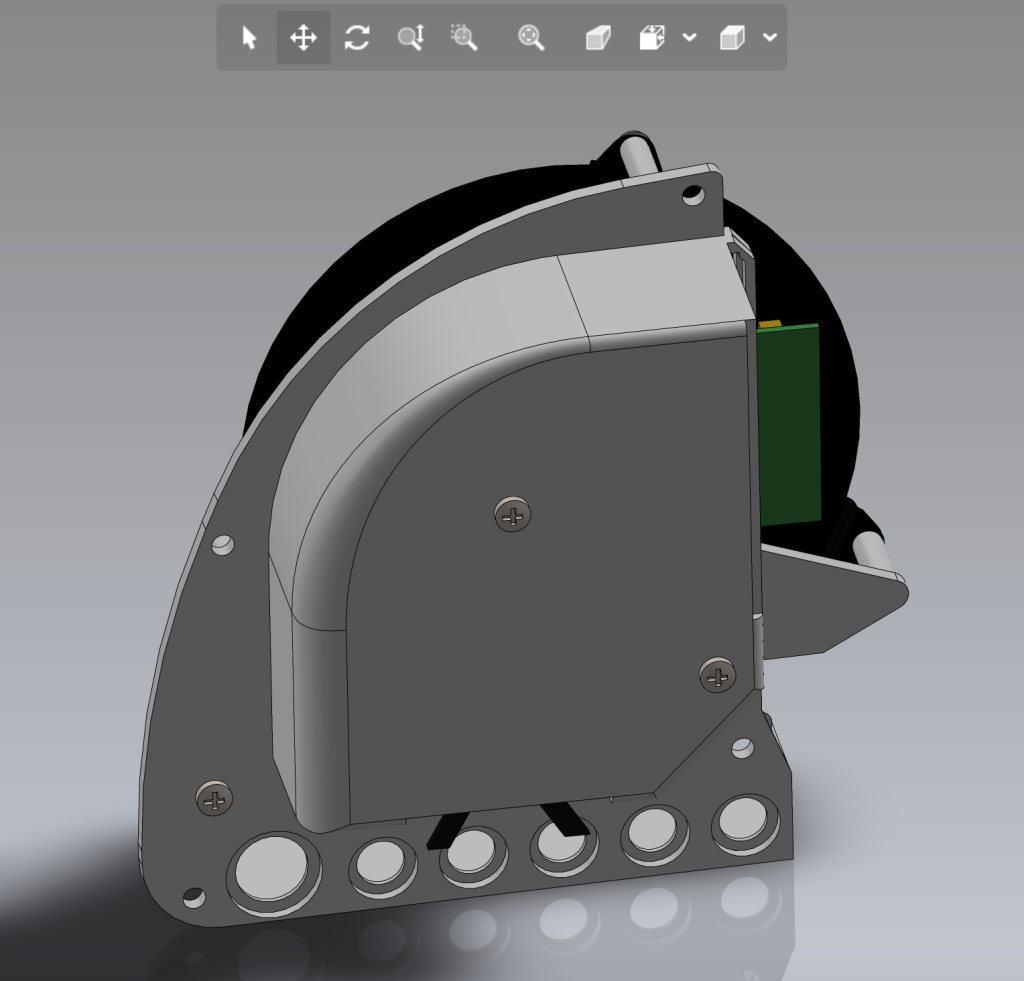

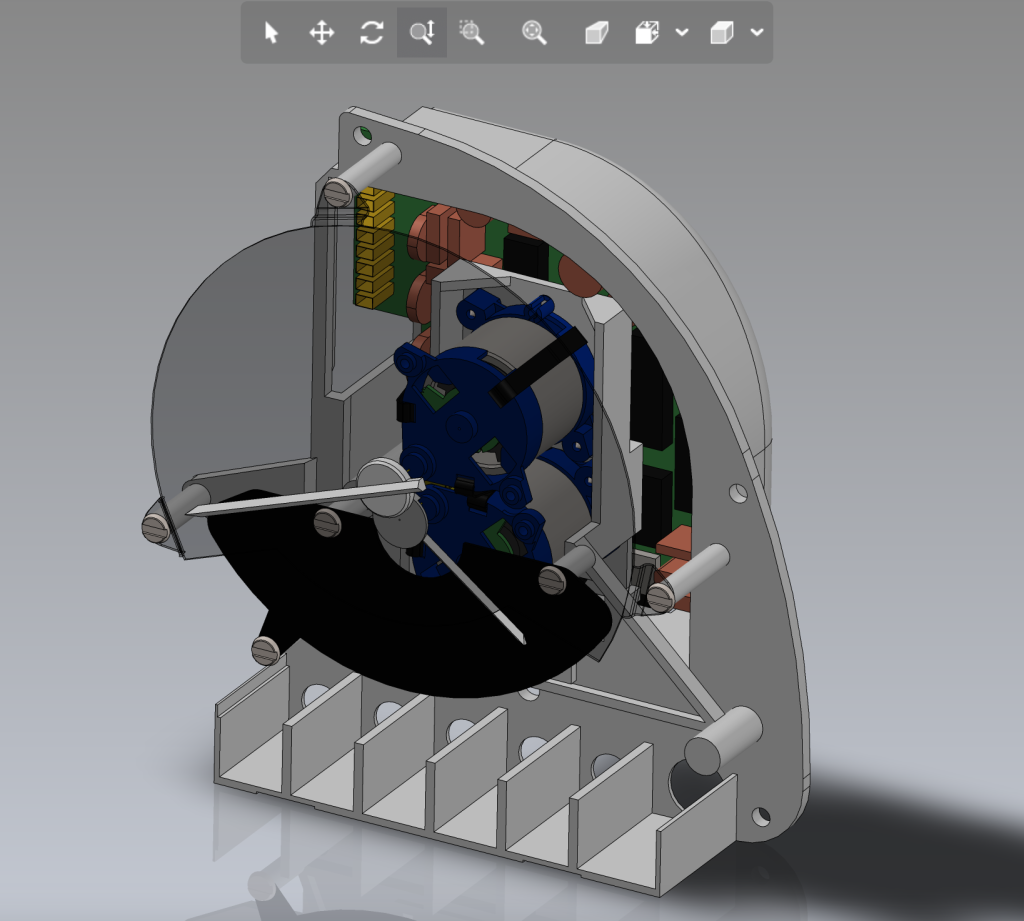

For this particular project, I chose to use an automobile tachometer. We used calipers, micrometers, depth gages, and feeler gauges to determine the dimensions and accurately model all the parts. I found springs and parts that were in a state of elastic deformation to be the most challenging to model. As much as I did lose sleep over this project, it was a great crash course into the extremely important world of 3D modeling and computer-aided design.

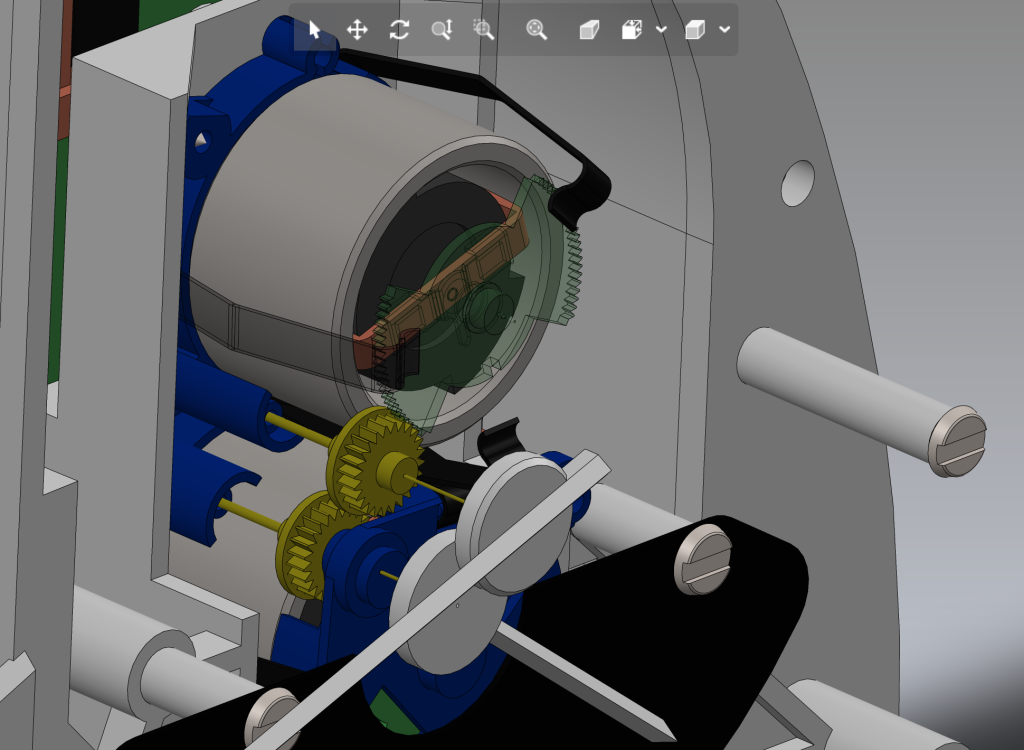

The inside of the tachometer with the main face transparent.