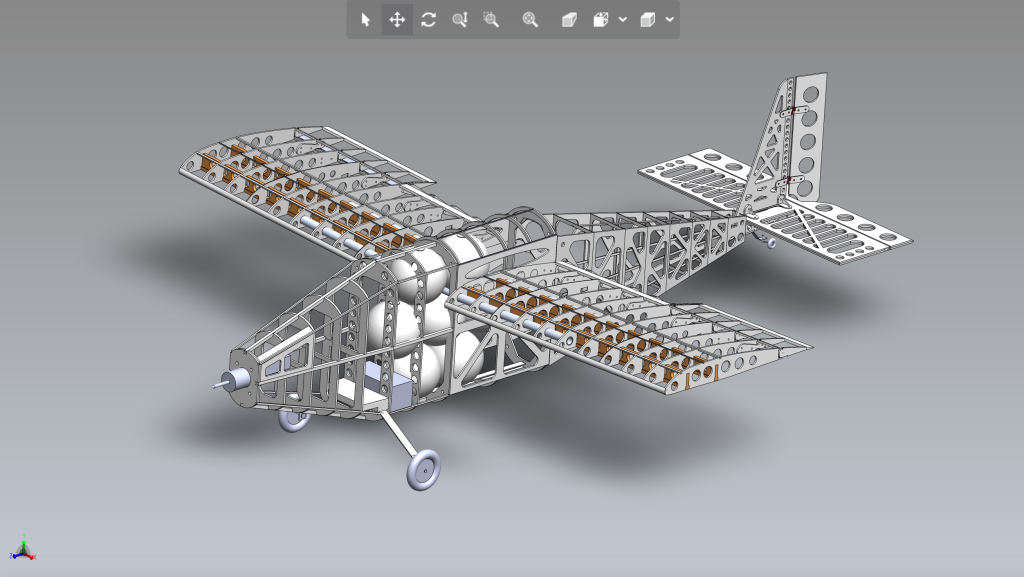

During my senior year of engineering school at the University of Portland, I led a multidisciplinary team of students and engineers to design and build a bush plane, from scratch, according to the rules set forth by the Society of Automotive Engineers (SAE) for that year’s competition.

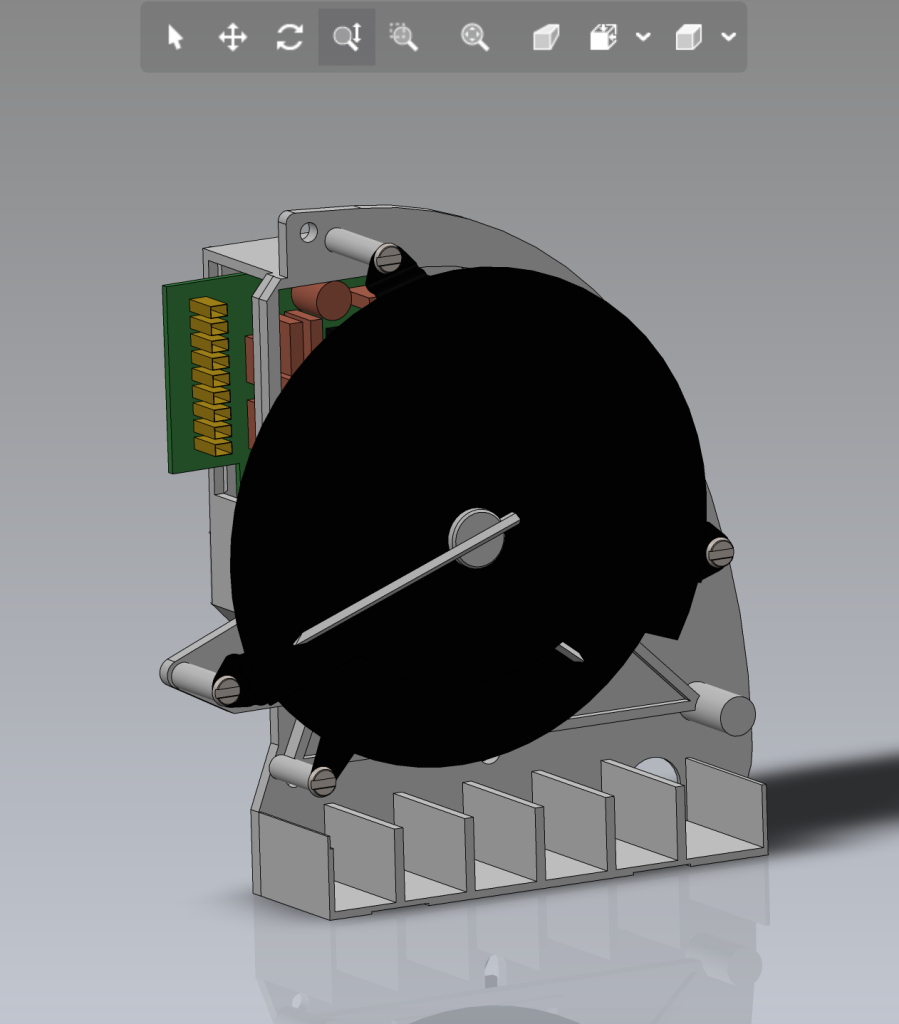

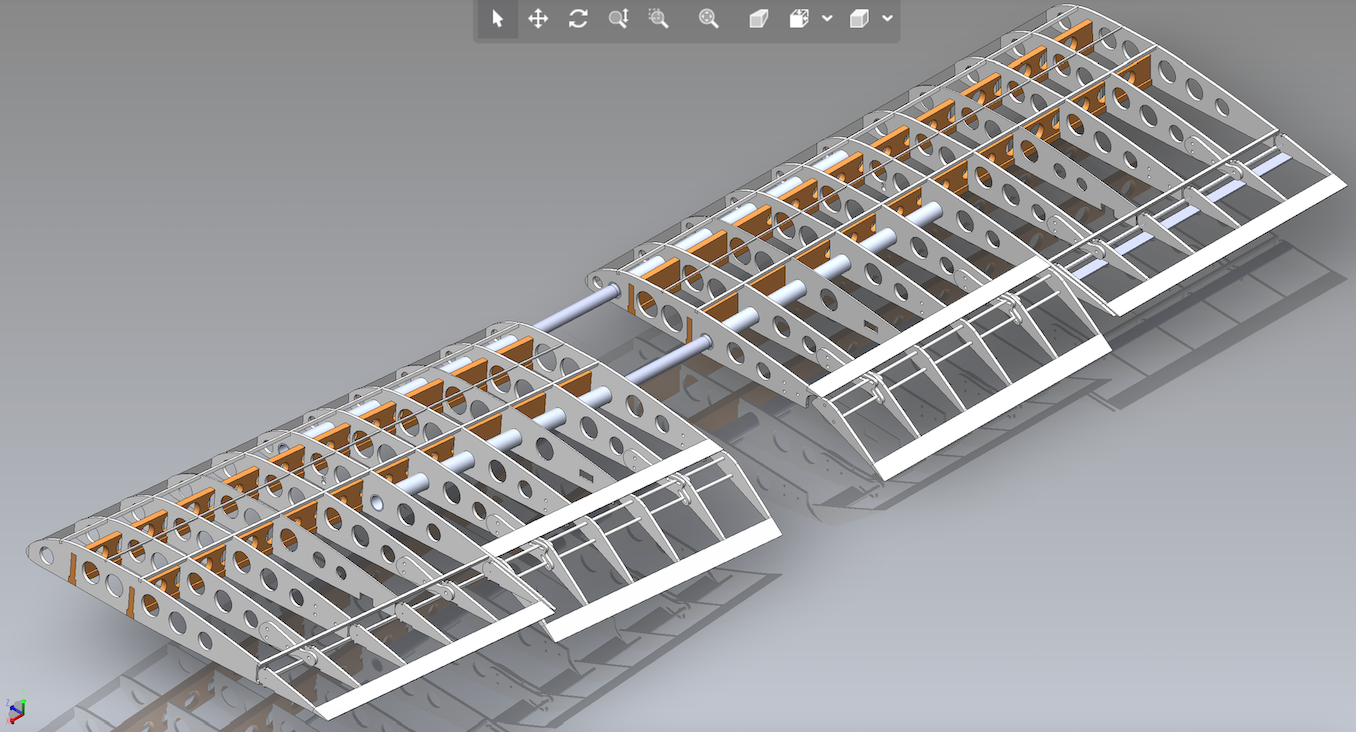

Entire Assembly

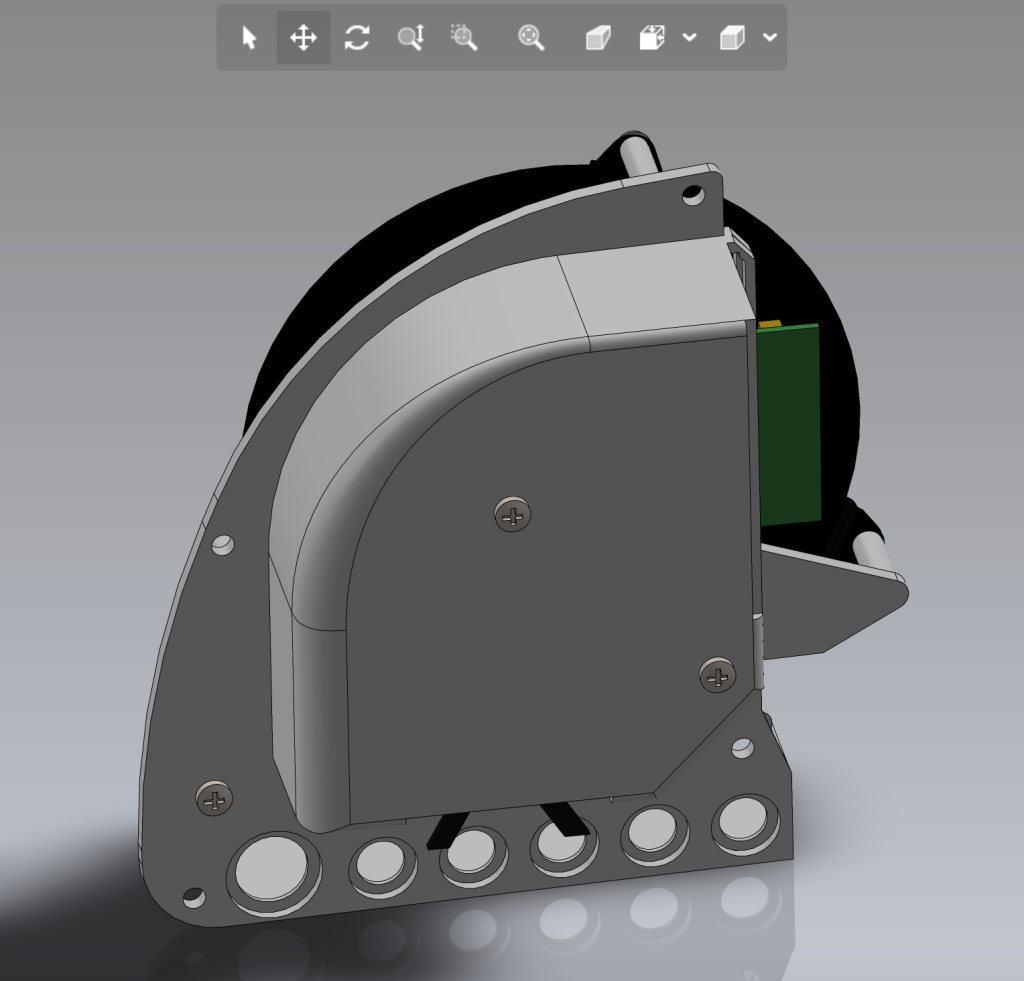

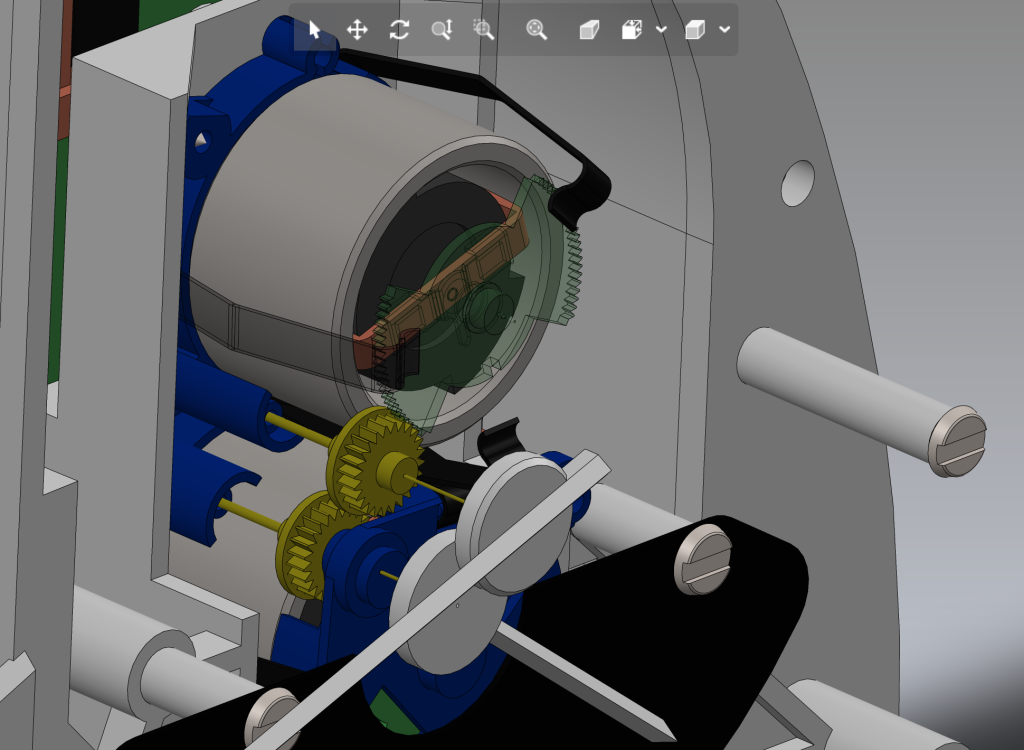

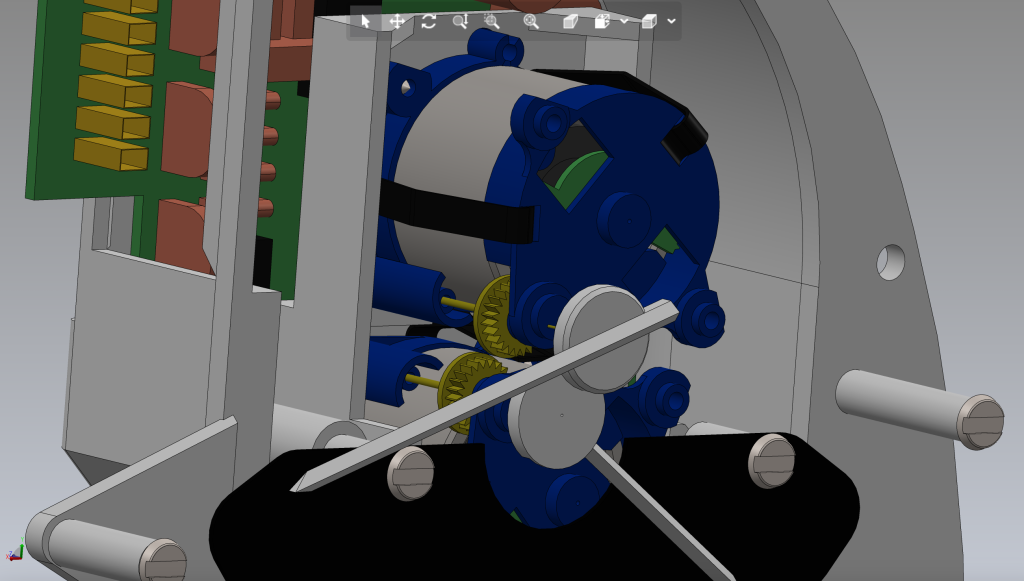

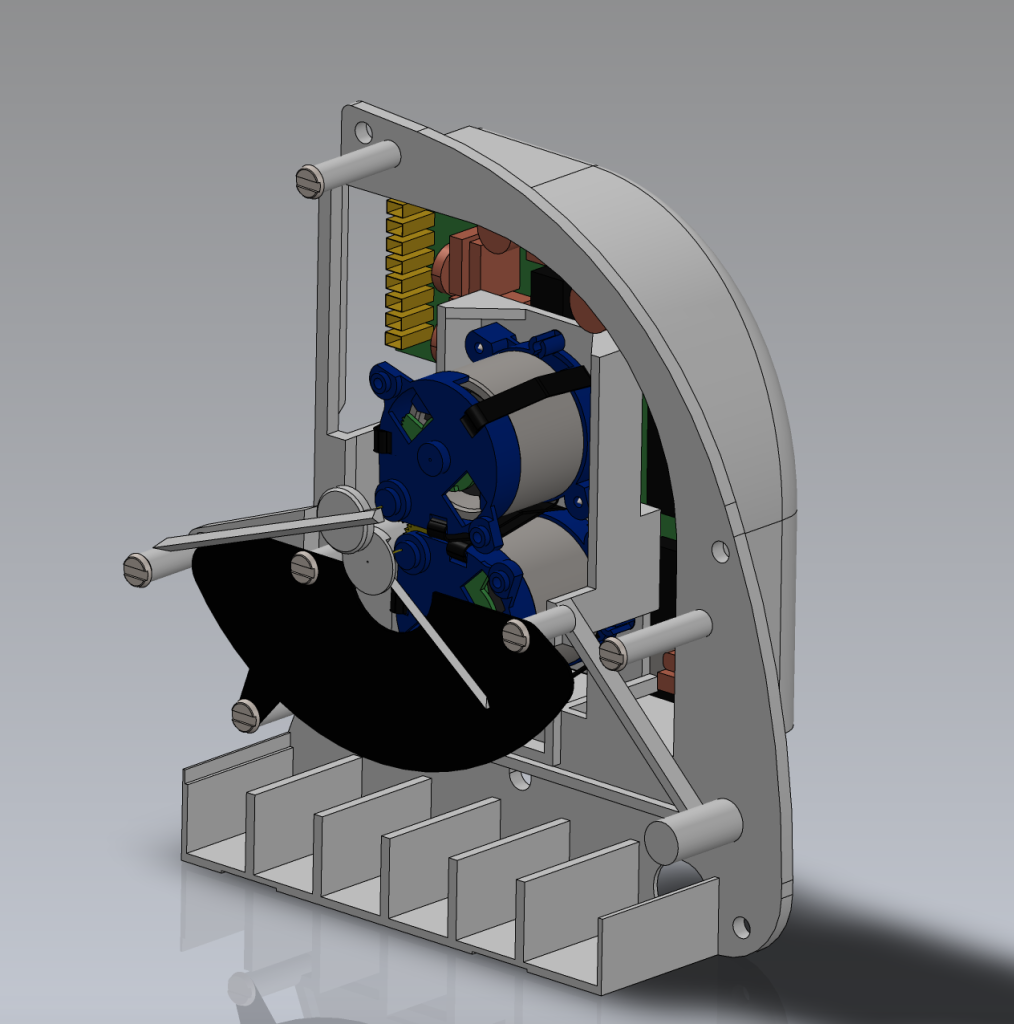

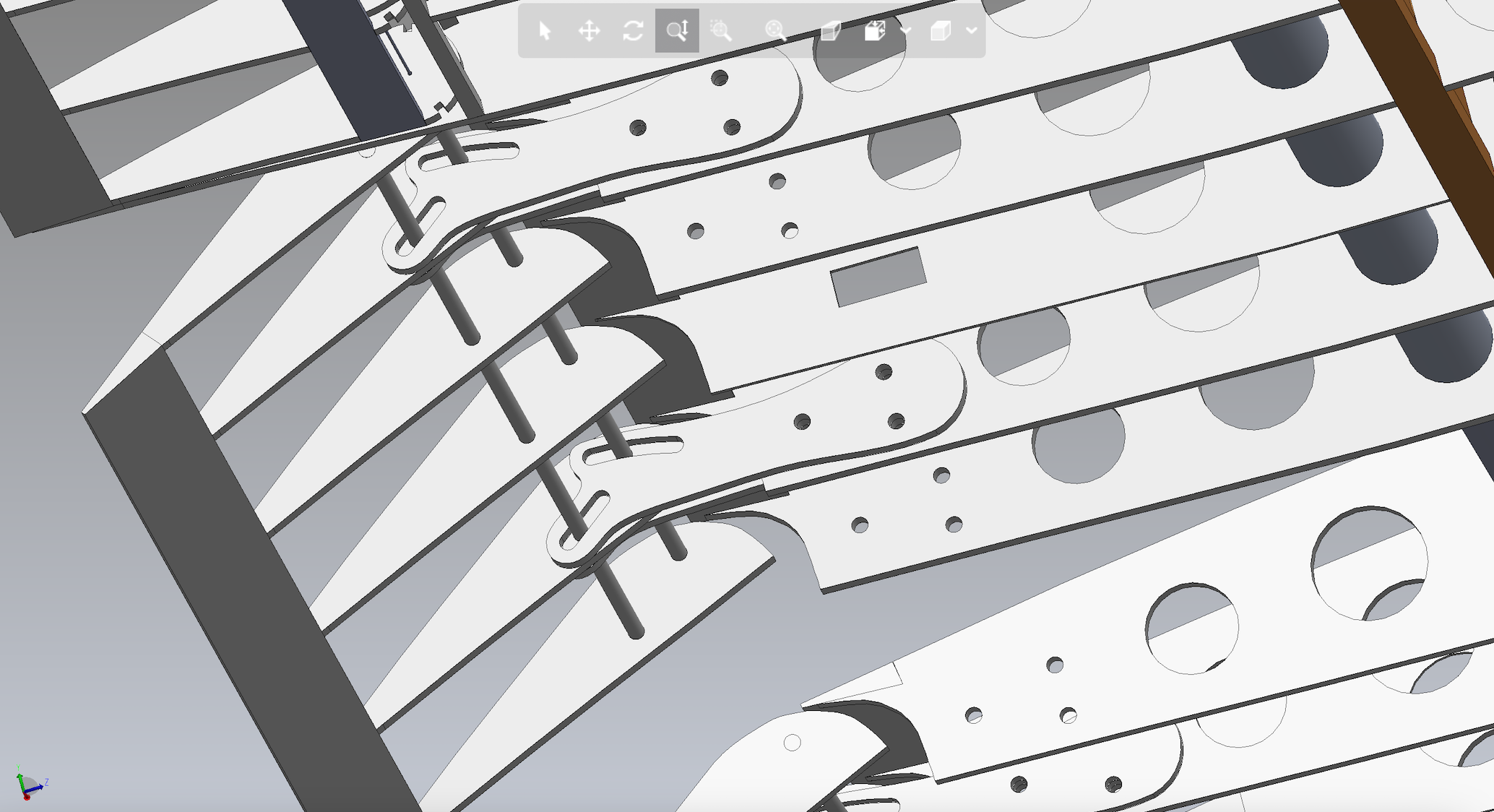

Slotted dynamic flap design (high lift device)

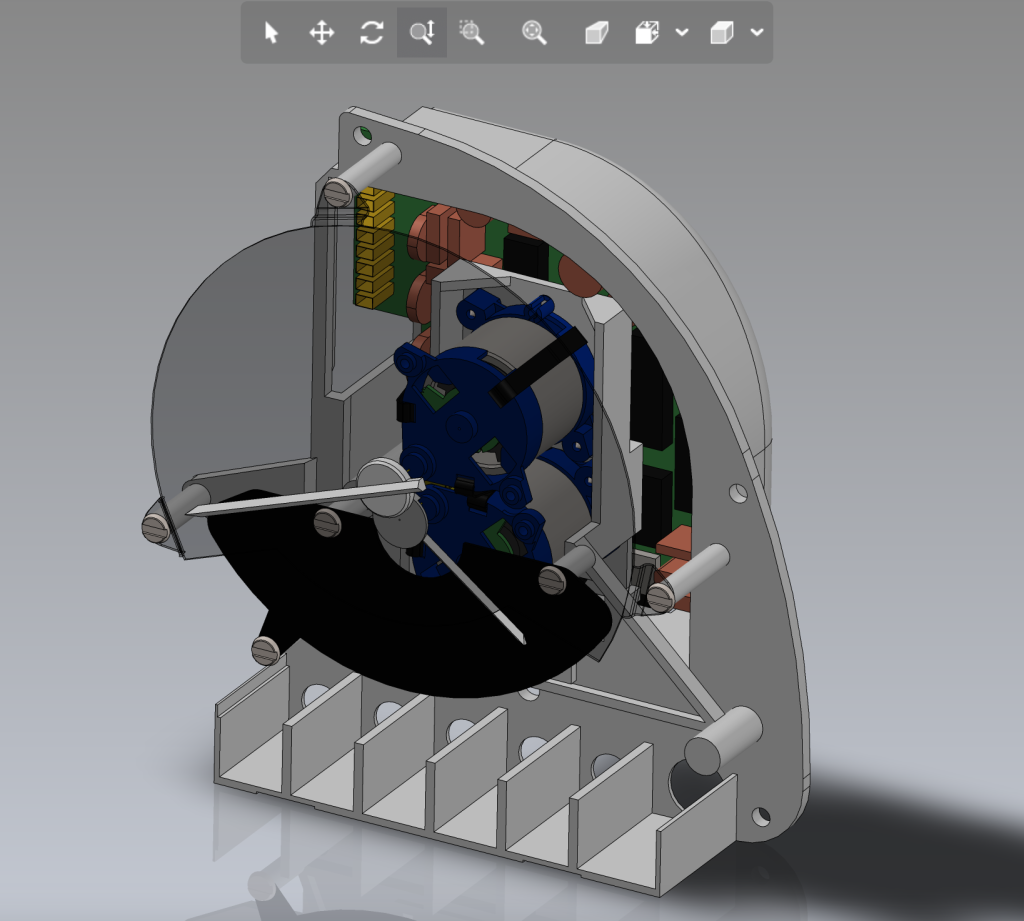

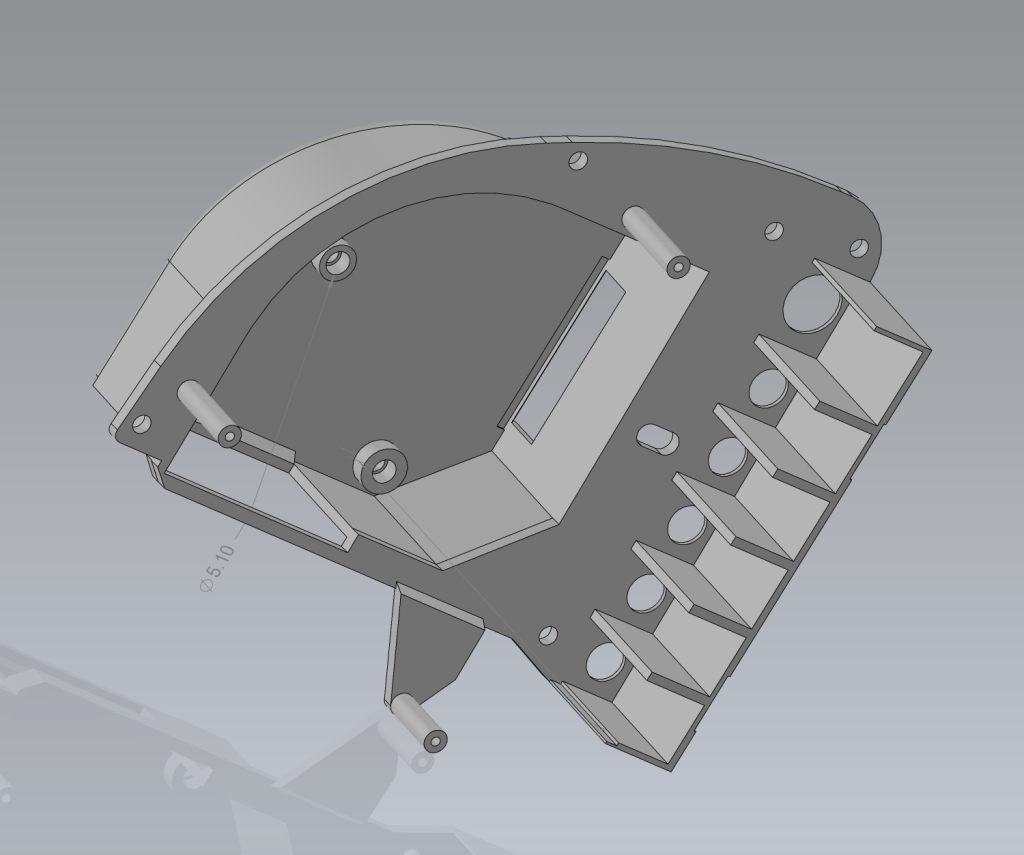

Wing Assembly

This project was put together by students at the University of Portland’s 2020 Capstone team. I oversaw the entire design and made changes where necessary, such as moving the center of gravity and the center of lift. I did the complete design and construction on the main wing. A NACA 4212 wing shape was chosen for its high lift and relatively low drag, especially at slow speeds. Flaps were also added to the wing assembly to create as much lift as possible in low-drag situations. This would make the aircraft take off in a much shorter distance, which was one of the items in the rubric given to the team by SAE.

The team was successful, and the University of Portland placed 20th out of 43 teams competing. This score was based off of the presentation only, as the competition was extensively modified due to the global pandemic. No schools were able to travel to Dallas to compete in person.